In DTC shipping, packaging includes all materials, from inner protective layers to the outer box, used to protect, deliver, and present a product. It serves both functional and strategic purposes.

Why Getting Your Packaging Right Matters

Today’s customers don’t just buy a product: they buy an experience. The unboxing moment is a critical touchpoint between brand and customer, especially in the DTC world where first impressions are formed the moment a package lands on the doorstep. A well-designed, neatly packed box can increase brand perception and create a positive experience. But a damaged product will hurt a brand’s image and make customers question quality.

Packaging sets the tone for how customers perceive your brand and whether they’ll come back for more. Perfecting your packaging reduces returns and negative reviews, while boosting customer loyalty and acquisition.

Understanding the Packing Hierarchy

Why Is There a Packing Hierarchy?

When you think about shipping, you might picture a single box going out the door. But at scale, DTC shipping involves a layered system. This is known as a packing hierarchy: a structured way of organizing how products move from warehouse shelves to shipping trucks and, ultimately, to the customer.

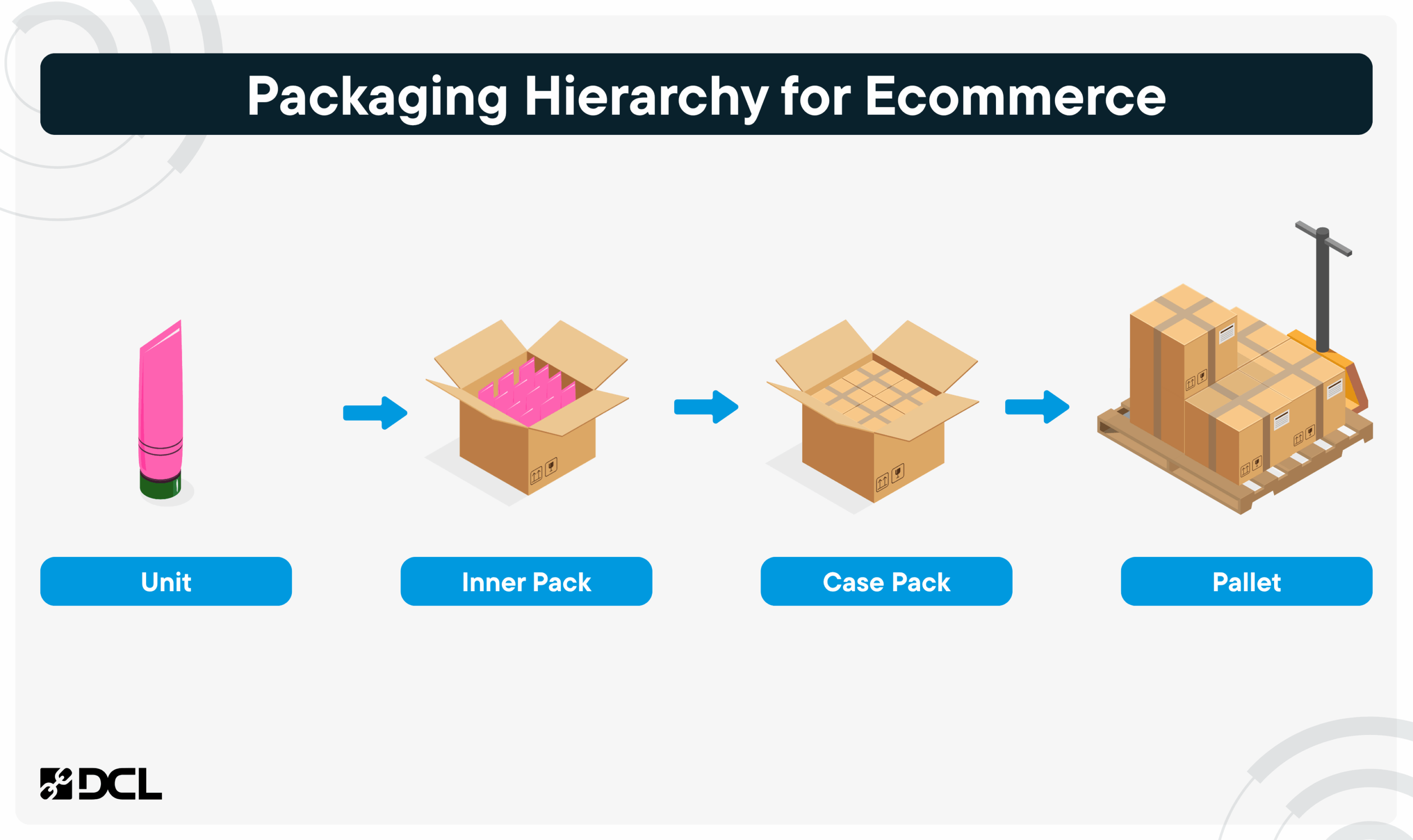

The hierarchy usually follows this progression:

- Unit: This is an individual sellable item. This could be a single bottle of cream (like in the graphic). If the unit is particularly small or fragile, it may have its own box (like extra sizes of earbud tips) that will be added by the manufacturer. But often it will be without any packing materials when it is being fulfilled by a 3PL.

- Inner Pack: This is the packaging that houses a small amount of similar or bundled units, often grouped together to streamline storage or fulfillment. A 3PL might put multiple units into an inner pack during the fulfillment flow, or as a pre-kitted bundle preparing for a special sale. An example of this might be three different scented candles, or flavors of protein powder in a “sampler pack.”

- Case Pack (Also known as a Master Carton): This is an even larger box containing multiple inner packs. These are used for shipping, storing, or selling in bulk. These are useful for wholesale, retail, or marketplace shipping (like Amazon).

- Pallet: This is a platform stacked with multiple master cartons, usually shrink-wrapped and ready for freight shipping to a distribution center or large retailer.

Why is the packing hierarchy important?

- Security: Fragile or high-value items will need multiple layers of packaging and dunnage to prevent damage or theft.

- Kitting: When multiple items are bundled together, such as sets, or subscription boxes, an extra layer of packaging helps organize the kit. Pre-kitting helps ensure bundled products can ship out quickly, like for a release day or newly launched product.

- Shipping and Regulatory Requirements: Items that are considered Dangerous Goods (DG), like aerosol sprays or batteries, often require a more specific labeling and packaging format. This is for security and safety measures when DG items are in transit.

- Inventory Management: Using standardized inner and case packs makes it easier for your 3PL to pack and count your items quickly and accurately.

Cost Considerations

Each level of the packing hierarchy carries its own set of cost implications, which is why understanding the structure is important.

- Storage Efficiency: Case packs and pallets allow for denser storage, which may reduce warehouse costs when you’re paying by the pallet or cubic foot.

- Box Assembly Fees: Some 3PLs charge extra for assembling more special packaging, such as kitting sets. There may also be added costs for storing specialized boxes (ones that take up more space than common materials).

- Material Sourcing: Many 3PLs offer packaging procurement services, but that convenience may come at extra costs.

- Shipping Costs: Using standardized case packs and optimized box sizes may reduce dimensional weight charges and minimize wasted space in transit.

Common Types of DTC Inner Packaging

Different DTC products have different packaging needs, primarily for security and branding reasons. Some products may be able to ship in inner pack only, if they are lightweight and not fragile. Others may require an inner pack, dunnage, and outer pack to ensure they arrive exactly the way they’re supposed to.

Corrugated Shipping Boxes vs. Mailers

When it comes to DTC fulfillment, the most common shipping formats are corrugated boxes and mailers. They are the most common because of their durability, cost, and potential to be branded or customized.

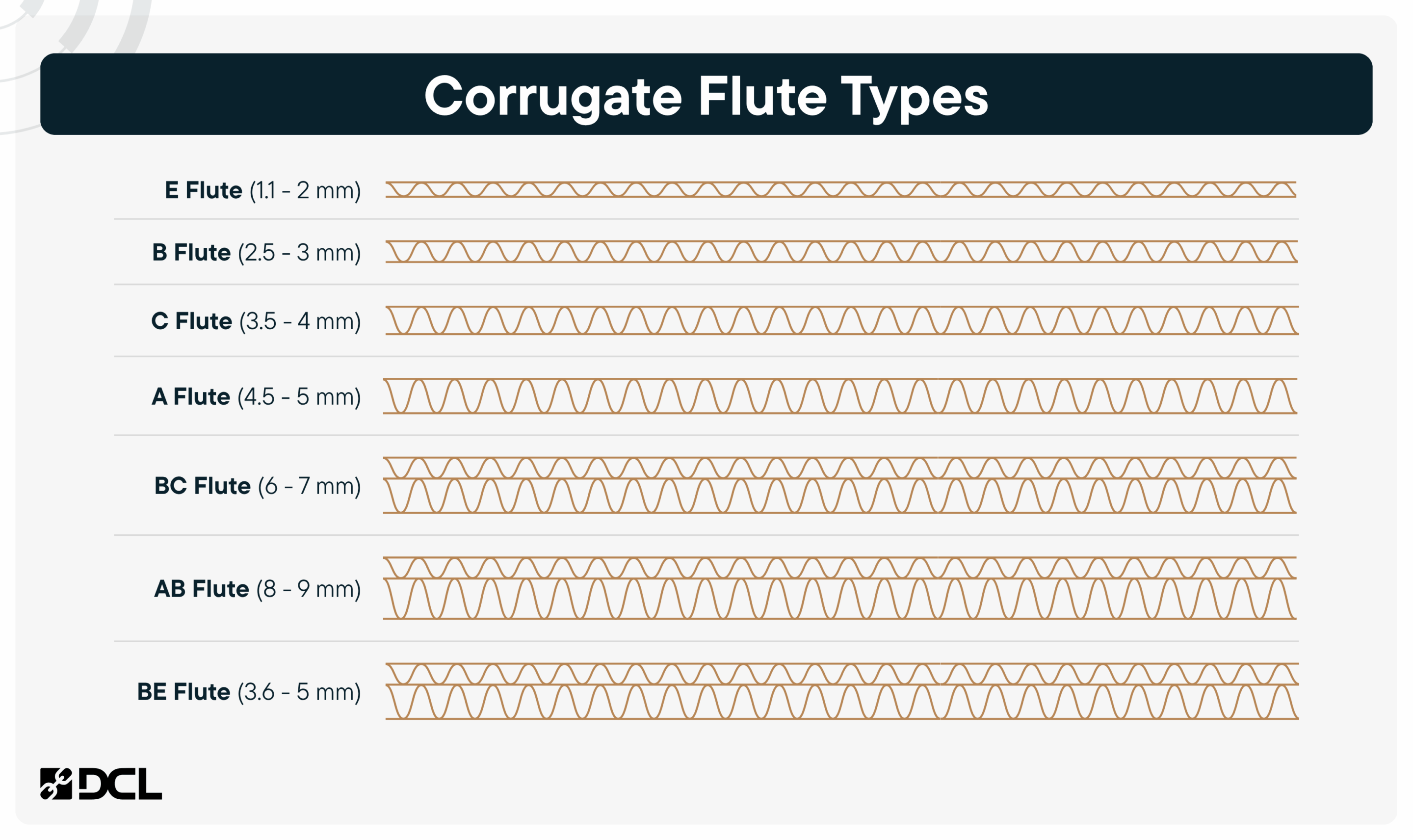

- Corrugated shipping boxes are made of durable, fluted cardboard and offer strong protection for heavier or more high value, fragile items. They are ideal for multi-item shipments, kitted sets, or anything that needs some more cushioning or structural support during transit. There are different flute types to choose from for your specific needs.

- Mailers include poly mailers, padded envelopes, and paper-based mailers. These are more cost-effective and suited for smaller, less fragile items. While they offer less protection, they’re cheaper and faster to pack, making them ideal for high-volume and low-risk products.

Considerations When Choosing Inner Packing

DIM weight

- Shipping costs are not based solely on package weight; instead, carriers calculate rates using dimensional weight, which factors in the size of a package relative to its actual weight. This pricing model is more expensive for oversized or inefficient packaging.

- Using overly large boxes increases shipping costs and causes inefficiencies in warehousing and transport. Optimizing your packaging dimensions ensures you’re not paying for unused space and helps maintain profitability.

Compliance with fulfillment automation

- Many modern fulfillment centers rely on automation to increase speed while still maintaining accuracy and cost-efficiency. Packaging that doesn’t work with the automated systems, including special sizes, reflective or glossy covers, can disrupt workflows and cause delays.

- Many 3PLs welcome customers’ custom boxes, but they must meet specific criteria, such as flat bottoms for conveyor belts, machine-readable barcodes, and an extent of uniform weight distribution for robotic handling. Failure to comply can result in added handling fees or slower fulfillment speeds.

User experience

- Packaging is an extension of your brand. Beyond protecting the product, it should deliver a smooth and intuitive unboxing experience. This includes using sturdy materials to prevent damage, clear visual cues for how to open the package, and thoughtful features that support returns, such as resealable closures or pre-included return labels. When done well, packaging reduces customer frustration, lowers return rates and elevates perceived product value, not just through aesthetics, but through practical, customer-centric design.

Eco-Conscious Packaging Trends

Sustainability has become a priority for many customers and even a differentiator for companies. As a result, more DTC companies are shifting toward eco-conscious packaging options that might include using recycled materials, plastic-free mailers, or perfectly sized packaging that reduces waste. While sustainable options may carry a slightly higher upfront cost, they may enhance customer loyalty and reduce environmental impact.

Retail-Specific Considerations

While DTC packaging focuses on the end consumer, retail fulfillment has its own rules. When selling through major retailers like Walmart or Amazon, packaging must meet compliance standards to ensure safe transport and also to integrate into their logistics systems.

Retail Requirements Example: Walmart Packaging Compliance

Walmart has detailed packaging requirements to streamline receiving at their distribution centers. One specific cost is the lumper fee, a charge incurred when third-party workers unload freight at the dock. These are usually fixed fees, but if your pallets are not properly packed, labeled, or stacked according to Walmart’s specifications, these fees will increase, or your shipment may be rejected.

Walmart enforces retail compliance standards that include:

- Case pack and palletization standards must follow strict configuration rules (number of units per carton, max pallet height, etc.).

- Correct barcode labeling is mandatory, including scannable GS1-compliant UPC or GTIN labels on all units and outer cartons.

- Packaging and labeling changes may require retesting or new UPCs.

- Product safety compliance involves submitting test samples and obtaining passing reports, especially for items containing chemicals, electronics, or battery components.

- Walmart’s has a Corrective Action Plan (CAP) process to be followed if a product fails safety, quality, or compliance testing

- Global Registration Services (GRS) and WERCS registration are required for certain categories like upholstered goods or chemical-based products.

Although investing in compliant packaging may appear burdensome, it is a critical requirement to enter one of the world’s largest retail chains. Failure to meet these standards can result in significant financial penalties or even contract termination.

FBA Packaging Requirements

If you’re selling through Amazon’s Fulfilled by Amazon (FBA) program, your packaging must meet their requirements.

Some expectations include:

- Boxes must be 6-sided and made of sturdy, corrugated cardboard.

- All boxes must be sealed securely with strong packing tape; do not use string or straps.

- Single-SKU boxes must contain units with the same SKU and condition.

- Mixed-SKU boxes are allowed but must include detailed box content information via Seller Central or a 2D barcode label.

- Use sufficient dunnage to prevent movement within the box.

- Acceptable: bubble wrap, foam sheets, air pillows, etc.

- Not acceptable: crinkled paper, shredded paper, packing peanuts.

- Boxes must pass a 3-foot drop test on various corners and edges.

Amazon also has strict standards for case pack quantity and dimensions. Incorrect packaging may lead to delays in receiving, product removal fees, or outright rejection of inventory.

For brands navigating both DTC and retail, understanding packaging systems for each channel is essential. A packaging solution that works for your Shopify orders might not be the same at Walmart or Amazon, and that’s where a thoughtful hierarchy and personalized packaging strategy will pay off.

Bottom Line

Packaging in DTC shipping isn’t just about getting a product from one place to another; it is a strategy that touches every part of your business. Understanding the full hierarchy of packing materials and boxes helps brands make smarter decisions for their shipping strategy. Whether you’re focused on creating a memorable unboxing moment, reducing damage in transit, or meeting the strict compliance standards of retailers, your packaging strategy matters.