What is Dimensional Weight?

Shipping carriers use a few specific ways to determine how much it will cost to ship a package. The size and weight of the shipment is one of the biggest factors.

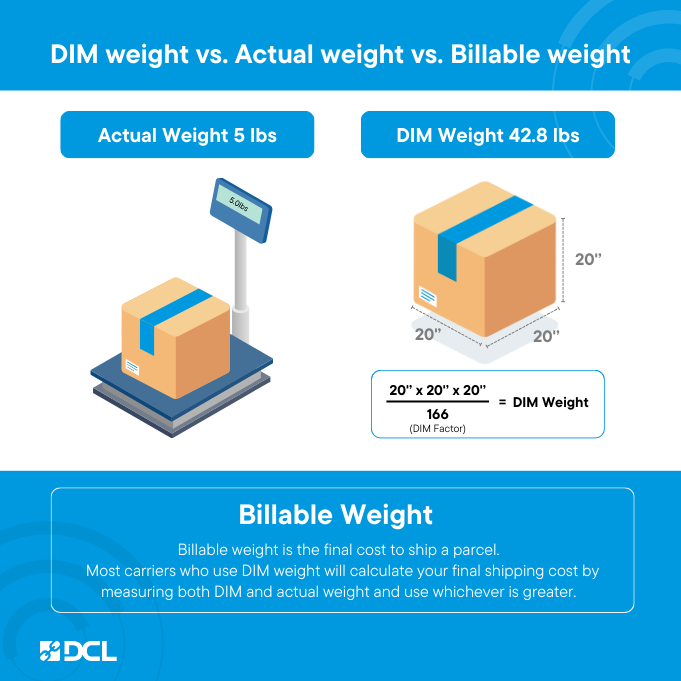

Dimensional weight, also known as volumetric weight, DIM weight, or cubed weight, is a pricing technique that shipping carriers use to calculate how a package will fit into their freight cargo. DIM weight is calculated by a formula using the volume weight of a package based on the dimensions of the box. Shipping carriers use this to ensure they won’t lose money if they have only large, lightweight shipments.

Not all carriers use DIM weight, but the major national companies like FedEx and UPS do. More carriers began using this pricing technique in 2015 when ecommerce saw a big boom. Shipping companies realized their trucks were getting full of boxes before they maximized the weight capacity. By adding DIM weight to their cost calculations, ecommerce merchants were forced to reconsider how their products get boxed up.

How is Dimensional Weight Calculated?

Dimensional weight is calculated based on the package’s length, width, and height. It takes the cubic volume of a package then divides that by the shipping factor.

The shipping factor or DIM factor varies from carrier to carrier, and service to service. Some merchants may also be able to negotiate a lower DIM factor at the start of a contract with a carrier. If no specialized DIM factor is considered, the default DIM factor is used.

Dimensional weight = (length x width x height of the box) / shipping factor

It’s important to optimize your product packaging for DIM weight. It’s a common transportation cost that merchants overlook, but it can be adjusted by re-kitting your product.

Many merchants might not realize how to calculate their DIM weight, which can lead to higher overall transportation costs. There are many fees that add up quickly, it’s important to understand everything that goes into your shipping bill.

In 2015, UPS and FedEx announced they would choose the greater weight between actual and DIM weight. Prior to that, most carriers didn’t use DIM weight. Now, a majority of carriers, large and small, have established DIM weights where they didn’t exist before. With the historic rise in online shopping smaller and regional carriers are looking for ways to maximize the space on their trucks, planes, and shipping containers, to stay competitive. DIMs help them do this.

What is Actual Weight in Shipping?

Actual weight is straightforward, it is the amount that a package weighs on a scale, not considering the size or volume. Also called physical weight, actual weight is sometimes used to calculate a package’s final cost of shipping.

Actual weight is used when items are very heavy for their size.

What is Billable Weight?

Billable weight how the carrier calculates the shipping cost. Billable weight varies from carrier to carrer, and service to service.

Most carriers who use DIM weight will calculate your final shipping cost by measuring both DIM and actual weight and use whichever is greater. This number they land on is the billable weight.

This is true for the major carriers like UPS, FedEx, and USPS. Smaller or regional carriers might have a billable weight that is closer to the actual weight, or a different calculation all together.

3 Ways to Optimize Shipping Costs

1. Update your packaging for reduced costs.

Different types of packing materials will create different weights for your packages. Moving from boxes to poly mailers, for example, might save you a lot per package, which adds up over thousands of orders.

If you’re looking to reduce your overall shipping costs, take a look at your packaging. It’s often an overlooked place where you can see significant cost savings with minimal changes. The top things to consider include product protection, branding and design, package size and weight.

2. Re-kit your products.

Kitting is a great way to lower the cost of packaging. Instead of packing each individual SKU separately into standard-sized boxes that might be too bulky, you can pack your items together in a custom-sized box. This reduces the size and dimensional weight of your parcels. It also saves on materials cost like package fillers and packing tape, which add up if your shipping volume is high enough. The savings that occur from reducing your packaging is one of the ways that kitting can boost your profit margin.

3. Partner with a shipping expert or 3PL.

By outsourcing your packing, labeling, kitting, and assembly work to a shipping expert or 3PL provider, you can benefit from their expert knowledge to get you the lowest costs. They’ll have the experience to maximize efficiencies in the type of packaging and kitting, which will net you higher profit margins in the long run.

If you are looking for support to lower your overall shipping costs, reach out for a quote. At DCL Logistics we often help high-growth brands rate shop for the best carrier service at the lowest cost. Plus we have tons of experience optimizing DIM weight for reduced shipping fees.

Tags: Calculators & Formulas, freight, Packaging