Written by the staff at Packlane.

Product packaging is usually the first thing customers see. Investing in custom-branded packaging that stands out in an aisle full of similar products is important. Just make sure you fully test any new packaging changes to ensure it doesn’t negatively affect your bottom line, fulfillment flow, or customer experience.

Packaging and shipping expenses can significantly influence a product’s overall price—which, if it’s too high, can turn off and disappoint customers. High shipping costs not only affect your business profits but also kill conversions. According to data from Statista, 25% of online buyers abandon their shopping carts due to unexpected shipping costs. But designing out-of-the-box packaging doesn’t have to put a dent in your shipping and operational expenses. It is possible to reduce your packaging costs and maintain your brand identity.

Here are the most effective packaging strategies you can implement that will not only save money but maximize your operating expenses and ensure high conversions.

1. Optimize your product box

First, you’ll need to think about the optimal size of your product box.

Businesses traditionally pack smaller products in large boxes, which can unnecessarily eat up space during transit if not packed efficiently. The volume and size of your package is what will determine the overall shipping cost, so starting with an efficient product box is very important whether it will be used as the shipping box, or it will get nestled into an outer box (sometimes called a carton).

Use these strategies to avoid using large shipping boxes:

- Design your mailer and product boxes to fit your goods snugly.

- Automate the packing process to select the optimal shipper box size for each product.

- Consider pouches or padded envelopes for smaller goods instead of boxes.

- Maximize your shipping density by packing as many products as you can securely fit in a single box.

2. Choose light weight, custom packing materials

Custom packaging is tailor-made for different product categories and helps you control what material and size you want to use which will save money in the long run.

The key here is to use the least amount of packaging while still ensuring your product will be secure during shipping and delivery. Even though you can’t make your actual product lighter, you can reduce the overall package volume and overall package weight with smart packaging—filling the void with less dense materials.

Here are some tips for strategized custom packaging:

- Consider light materials like SpiroPack void fill, custom inserts, or air pillows that snugly fit around your product, to keep your product safe while keeping the weight lighter.

- Use poly mailers, which take up less space than boxes for soft items like clothing or bed sheets.

Remember, custom packaging isn’t only about delivering an exceptional unboxing experience; you can use it as an opportunity to optimize your product’s packaging and reduce shipping costs.

3. Minimize DIM weight to lower shipping fees

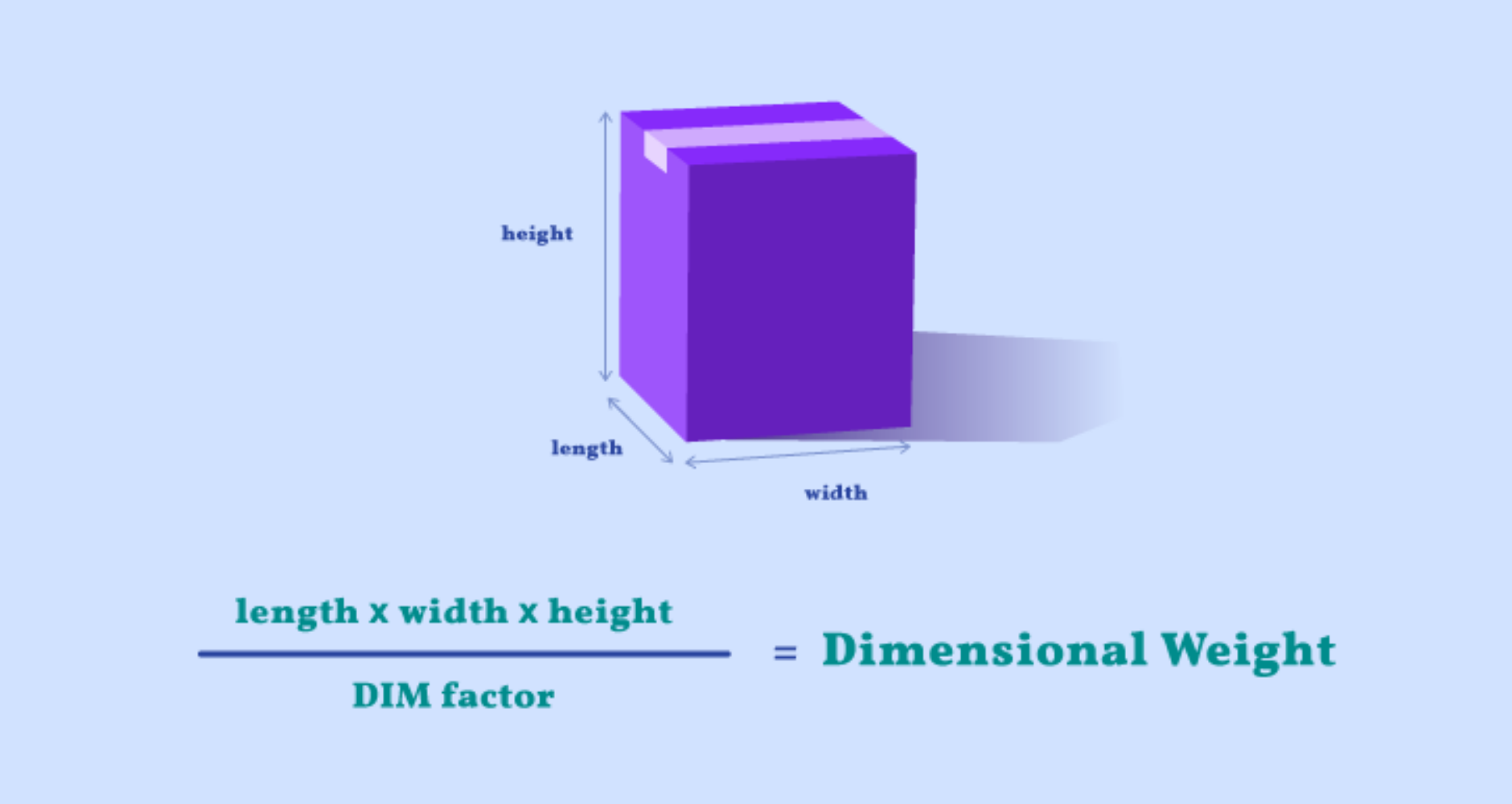

UPS and FedEx introduced dimensional pricing, which calculates a package’s dimensional weight (DIM weight) which includes volume along with actual weight and size of the package. Dim weight pricing rewards those who don’t overpackage boxes to increase shipment density during transit.

The formula for calculating DIM weight is the length of the product box times its height and width, divided by the DIM factor.

DIM weight equals [Length x Height x Width / DIM factor], where DIM factor = 139.

Each carrier has a default DIM factor denominator of 166. The start of your contract with a shipper is the only time you can negotiate a lower DIM factor.

Light weight packing materials are a great start to minimizing DIM weight, but not enough. You also need to consider the outer shipping box.

Avoid one-size-fits-all boxes for all your products, and instead, use custom packaging to minimize DIM weight pricing. Other strategies to reduce DIM pricing include using smaller boxes, padded envelopes, and shipping the maximum number of items possible in one single box.

4. Pack for safety to minimize damages and eliminate returns

According to of customers reported damaged products being a major reason behind frustrated item returns.

Let’s face it, shipping can get a little bumpy, but proper product packaging planning can prevent even more transit damage. If you put minimal thought into product packaging, it can result in breakages and a loss of customers and business revenue.

Besides frustrated customers, return shipping is another cost that’ll add to your shipping expenses.

You can avoid this altogether and ensure product safety:

- Add efficient and light void fill like SpiroPack and tissue paper to minimize the product movement within the box.

- Choose the correct box size—you don’t want to be shipping air!

- Choose a reliable and suitable carrier or shipping service.

5. Consider the quality of corrugated

Custom corrugated boxes are sturdier and offer more protection and security. Research suggests that the global market value of corrugated box packaging is expected to reach $294 billion by the end of 2023—and for good reason. When you pack your products using corrugated boxes it significantly reduces the risks of product damages.

Apart from this, other benefits of corrugated boxes include:

- Optimizing carrier space by allowing you to stack more boxes on top of another.

- Allowing you to save money on storage and transportation.

- Offering better overall protection and robust product security.

6. Calculate all shipping rates

Once you’ve taken care of all shipping-related factors and implemented strategies to reduce costs where possible, include all these shipping costs when billing your customers so you don’t have to pay for it all yourself.

Shippers and carriers have unlimited product charges; unless you wish to offer sweet deals to your customers by paying extra out of your own pocket, include these in your overall product costs.

- Product delivery speed

- Weekend delivery rates

- Fuel surcharges

- Signature fees

- Package tracking/delivery confirmation

- Delivery insurance

Some more tips on ensuring lower shipping costs are:

- Eliminate wrong address shipping penalties and reduce surcharges by automatically verifying shipping addresses.

- Ensure you regularly spot-check regularly-updated shipping rates to avoid business losses and recover incremental shipping charges.

- Choose a carrier that offers discounts or reasonable shipping costs.

Bottom Line

Shipping comes with unavoidable costs, and some attention to your packaging details can significantly reduce your shipping rates and increase business profits. However, reducing packaging costs doesn’t mean jeopardizing your brand integrity and choosing low-quality materials to save on shipping expenses.

Understand where your packaging money goes. Are you overpaying because of DIM weight, or product damages? Once you identify the places that could be more efficient, reach out to your fulfillment provider to make adjustments.

The new year is a great time to review your packaging and shipping strategies. The downtime after peak season is the perfect time to revisit your packaging, to ensure it’s optimized for product protection, low-costs, and overall efficiency.

About Packlane

Packlane helps trendsetting companies create branded custom packaging and boxes. They specialize in using sustainable materials and have services to build tailor-made packaging that meets the needs of small and medium-sized ecommerce businesses. Packlane can help your brand ship orders simpler, easier, and more affordably, so you can deliver the ultimate unboxing experience for your customers.

Get started with Packlane today!

Tags: Fulfillment Costs, Packaging