Dimensional weight is one of the most influential factors in your overall shipping cost. Most domestic shipping carriers use dimensional weight as their primary method of calculating the cost of shipping a package.

In this post, we’ll explain everything you need to know about dimensional weight: how it’s calculated, why it matters for your product management, how it’s different than actual weight and billable weight, and best of all, how you can avoid it (or at least help you to reduce it).

- The DIM weight of your packages is one of the biggest factors that will affect your final shipping invoice.

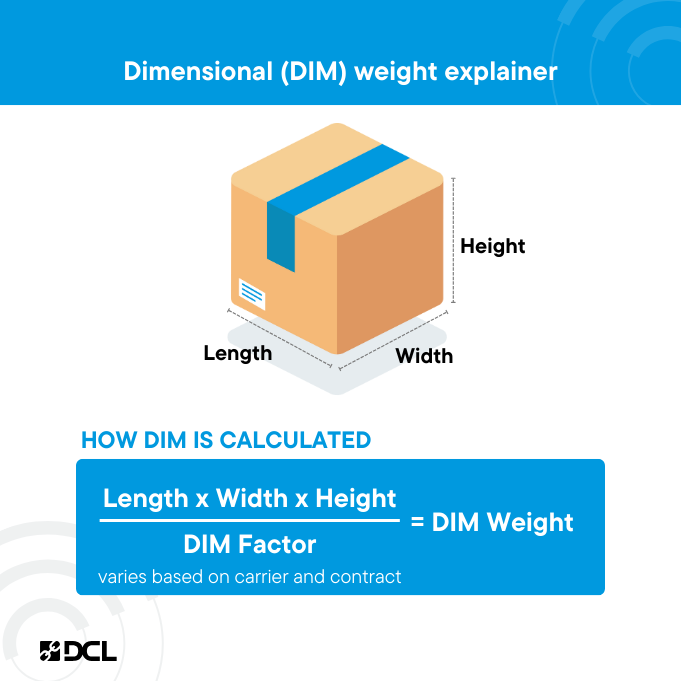

- DIM is cubic weight or volumetric weight, which means it’s calculated by multiplying the length, width, and height of the package, then dividing that by the DIM factor.

- Most carriers use a DIM factor of 166, but this number is negotiable when signing a contract, and it may vary depending on the service and carrier you choose.

- Some carriers and shipping services may use a parcel’s actual weight rather than the DIM weight, it all depends on how the two compare.

- DIM weight is more beneficial for shipping heavy products that are small, or light items that are very large.

What is Dimensional Weight?

In shipping, not all weight is necessarily created equal. What you consider in your mind to be soft and light could conceivably take up a lot of space in a shipment. That might hinder carriers from shipping it with other products at the same time.

To put it simply: It costs more to move a truck full of kettlebells than one filled with packs of premium headphones. The weights take up more space, they cost less, and it would take more shipments for the carriers to make a large enough profit to make it worth it.

That being said, dimensional weight, also known as volumetric weight, DIM weight, or cubed weight, is a pricing technique used by shipping companies to ensure that they don’t lose money on large, lightweight shipments (like a truck full of blankets). Dimensional weight is calculated with a formula using the volume weight of a package based on the dimensions of the box.

How is Dimensional Weight Calculated?

While physical weight is the weight of the shipment according to the scale, dimensional weight is calculated based on the package’s length, width, and height. As a result, that oversized boxful of blankets might be considered heavier than a box of headphones. Dimensional weight takes the cubic volume of a package then divides that by the shipping factor (whether international, domestic, or other less common factors).

Dimensional weight = (length x width x height of the box) / shipping factor

Here’s an example: You have a box measuring 48 inches x 20 inches x 20 inches. If the three dimensions are multiplied—48 x 20 x 20—it equals 19,200 cubic inches, which is the cubic volume of that package. Carriers like FedEx, UPS, and DHL Express take that number and divide it by the rates for their shipping—different types of shipping will incur a different division number. The carriers just listed will use 139 in / lb for domestic rates, and FedEx SmartPost and DHL will use 166 in / lb as the dimensional factor for international shipments.

Dimensional weight calculations can vary depending on the carrier, the shipment, the journey of the package and more. If you ship our example box domestically, the dimensional weight equals 10,240 divided by 139 — 73.67lbs.

Can I Avoid the Cost of Dimensional Weight?

If completely unaware of these charges, a company new to shipping and logistics might incur a steep dimensional weight cost without even realizing it. And, yes, to some degree, dimensional weight can be avoided or at least reduced. Steps to reducing it:

- Package your products with as little extra room as possible. Third-party-logistics (3PL) companies that help sellers manage their shipments often provide packaging services to maximize the space and reduce shipping costs. Commonly they’ll remove a product from its original box then repackage it to better utilize the space.

- Opt for an alternative service that has lower dimensional weight pricing.

When is Dimensional Weight Applied?

Not all shipping carriers use dimensional weight as their primary determiner of shipping cost. The major carriers like FedEx and UPS have used DIM weight since 2015.

DIM weight comes is useful for heavy products that are small, or light items that are very large. For example a set of hand weights are relatively very small, but also very heavy. Using DIM weight allows the size of the package to be considered, not just the actual weight.

Freight companies that use DIM weight to calculate billable shipping often measure both DIM and actual weight and use whichever is greater. This ensures the carrier doesn’t lose money on bulky, light items.

DIMs are a major factor for more than just the bigger domestic carriers (UPS and FedEx). As shipping volumes continue to increase at an historic rate, smaller carriers are looking for ways to maximize the space on their trucks, planes, and shipping containers, to stay competitive.

One way they are doing this is by establishing DIM weights where they didn’t exist before. This is having a major impact on the cost of shipping a product and may require shippers to re-strategize the types of shipping boxes and product packaging they use.

Want to know more about DIM weight? Here are some related topics:

If you are looking for a 3PL to help you understand concepts like dimensional shipping or require logistics support we’d love to hear from you. You can read DCL’s list of services to learn more, or check out the many companies we work with to ensure great logistics support. Send us a note to connect about how we can help your company grow.

Tags: Freight