The next few months are predicted to have the highest online sales in retail history. Everyone in the retail and shipping industry—from carriers, to fulfillment companies, distribution centers, and of course sellers—are all preparing for an unprecedented season. There may be unexpected challenges (it’s always something!), and the more prepared you are, the easier you can roll with any hiccups.

We’ve put together a list of proactive measures we’re taking at DCL Logistics this season, and what sellers can do to minimize the impact on their shipments.

How Did We Get Here?

The biggest challenge every peak season is getting parcels to customers by specific dates (namely Christmas). Plus customers have become accustomed to instant deliveries, and while that’s possible for certain items at certain times of year, during the surge of holiday shopping it’s just not always obtainable.

During a year where supply chain bottlenecks and shipping delays are rampant, this will not be a typical Q4. Because the pandemic severely limited the safety of in-person shopping, online shopping is at an all time high. An already intense season is now primed to be truly unprecedented. There is no way that all of these factors will result in anything but overloaded carriers and delivery delays.

What Carriers Are Saying

Even though all carriers are investing heavily in their infrastructure and staffing, they continue to warn sellers that everyone should expect slower delivery speeds this year. Is this just for precaution? Or will there really be delays? No one knows until we’re through but it’s best to air on the side of caution and clarity, at least to manage consumer expectations. One thing that is true of all carriers, none of them have guaranteeing delivery speeds over the holidays.

FedEx released a great list of tips for sellers during this time. Their advice points to heightened communication with partners and customers, proactive inventory management, and being smart about your sales strategy. Number one on their list is incentivizing customers to shop early.

DHL released a post that cites that the busiest part of peak season (Black Friday to Christmas) will have “delivery volumes over 40% higher than the average daily volume.” Their tips include a fair list of basic packaging rules including maximizing the space within your boxes, and ensuring that all products are well packaged and labeled. No one wants a lost package on account that the label came off!

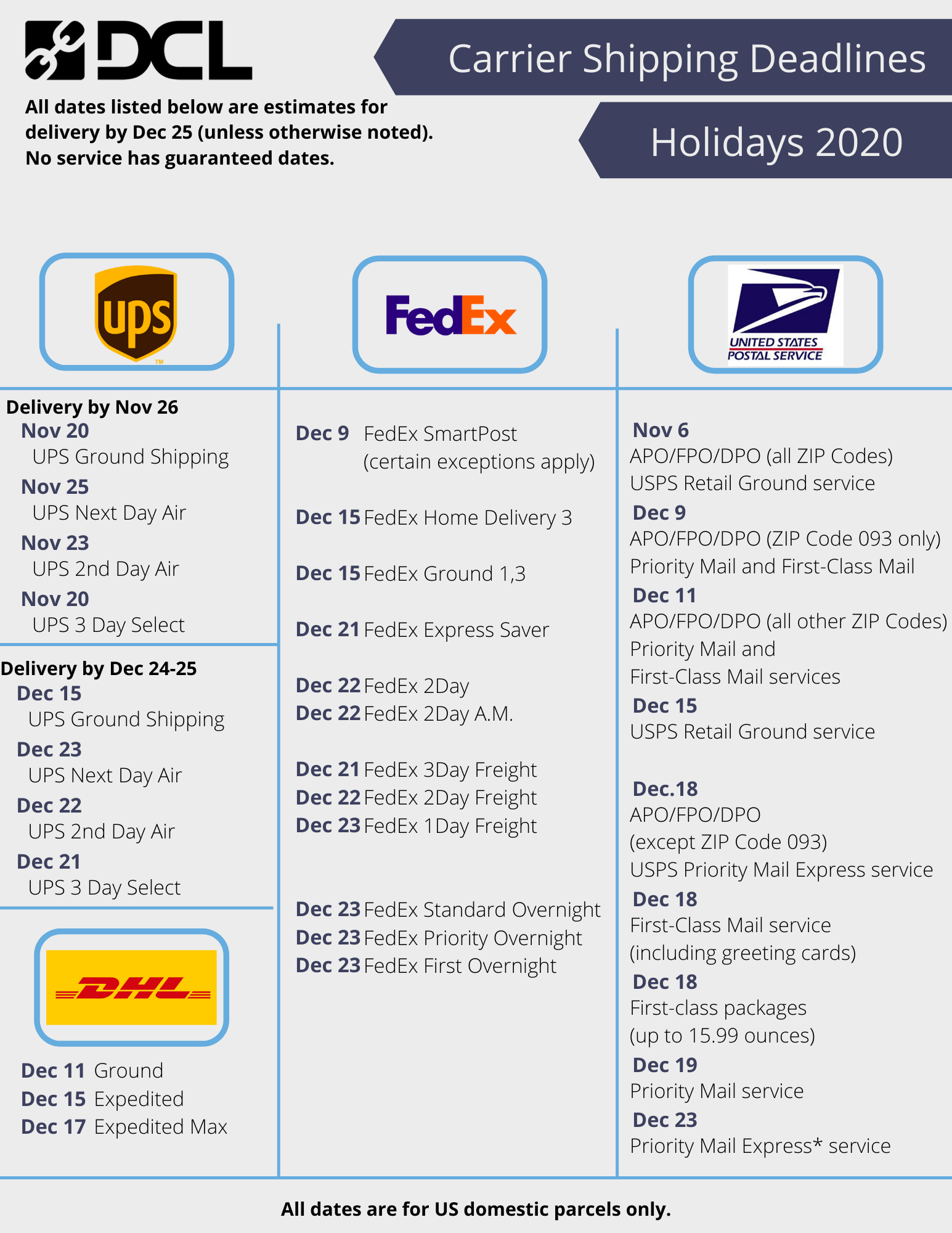

The number one piece of advice that is consistent throughout all carrier announcements is this: know exactly what your shipping deadlines are, and communicate them very clearly to customers. Holiday shipping deadlines have been posted from FedEx, USPS, and UPS.

Solutions for Sellers

If you are shipping in-house these tips aren’t new but they are good reminders or how to keep agile in a shifting situation. If you have outsourced your fulfillment or shipping to a 3PL or third-party, don’t rely on the fact that your partners are taking all the precautions. Connect with your account manager to ensure your business is supported during this peak season.

Communicate with Your Customer

The number one thing you can do to ensure customer satisfaction is ship early and prepare your customers for longer delivery speeds. It may seem like common sense, but it’s worth noting. If a customer is surprised that a package came early, that’s ideal. But if their package comes later than they expect, that could result in negative online reviews, or lost customers.

Update Forecasts for Carriers

Communicate clearly and frequently with all partners too. At DCL Logistics, we plan to update our shipping forecasts often and share changes or updates in real-time. This is critical as some of the carriers will cap their daily intake for certain service lines. Some carriers try to hold lanes or space for larger shippers or their top customers to try to improve the quality of the shipping process and minimize delays. It’s not perfect nor does it guarantee anything, but it can help. It’s so important that 3PLs aggregate their clients’ forecasts, check for accuracy, and provide that information to the carriers. It’s equally important for sellers to keep their 3PL updated on exactly their forecasts.

Have a Backup Carrier Option

If possible, sellers should have an alternative carrier in the unlikely event that the primary carrier has a major issue. With all the twists and turns of 2020 so far, it seems that truly anything can happen! Having a backup will make it easier to switch to an alternative carrier to minimize any disruption. UPS has gone as far as encouraging shippers to find alternatives shipping methods as they face tighter capacity over the holidays.

“We work with our customers to help them rethink their operations via buy online pick up in-store, different timing for their promotions and different availability of their packages,”

Oftentimes, sellers rely on a sole carrier or carrier service, but for uncertain times it’s good practice to find a complementary carrier and service that they can easily switch to in case their primary is falling short of expectations. For example, if a seller is using UPS Surepost, they may want to consider having an account or integration setup with USPS as a backup. A good inside tip: USPS has to accept all freight, while FedEx and DHL have been known to stop accepting new accounts. They should understand the rates that they would get with the backup carrier so there aren’t any surprises.

USPS has to accept all freight, while FedEx and DHL have been known to stop accepting new accounts. They should understand the rates that they would get with the backup carrier so there aren’t any surprises.

Create a Carrier Contingency Plan

It’s actually not uncommon, especially over the holidays, that a carrier truck doesn’t have the space on their truck to pick up all the outbound shipments from a warehouse. While these carriers will make an effort to find another truck in their fleet to pick up the extra cargo, it’s not guaranteed so it falls to the seller and/or 3PL to move the packages that haven’t left the building on schedule. To mitigate this, you’ll need a secondary approach to ensure your packages don’t sit and wait. Your fulfillment center should have a backup plan to have the packages taken to the distribution center. This often comes in the form of a private freight company, or a proprietary vehicle that can take last minute hauls to the distribution center.

At DCL we are working with carriers to increase the frequency of pick-ups, although not all will. If carriers can’t increase pickups, we’ll use our own DCL truck to take freight to the carrier terminal when that is permitted. Bottom line, make sure your 3PL is doing everything they can to ensure that packages aren’t being left behind or getting delayed.

Here’s to a successful and smooth holiday season this year! If you are looking to partner with a 3PL who can help build an agile shipping strategy and mitigate shipping delays, we’d love to hear from you. DCL has many value added services and a proven track record of excellent fulfillment.