It is easy to get confused when hearing the acronyms for truckload shipping and less-than-truckload shipping as you try to decide which one is right for your specific needs. Both full truckload (FTL or TL) and less-than-truckload (LTL) options have their place in the freight shipping industry. Choosing the right freight shipping method depends on several variables, including the size and weight of your shipment, freight classification, and delivery timelines. It also might make sense to partner with a third-party logistics provider (3PL) to help manage your freight shipments.

LTL and FTL Explained

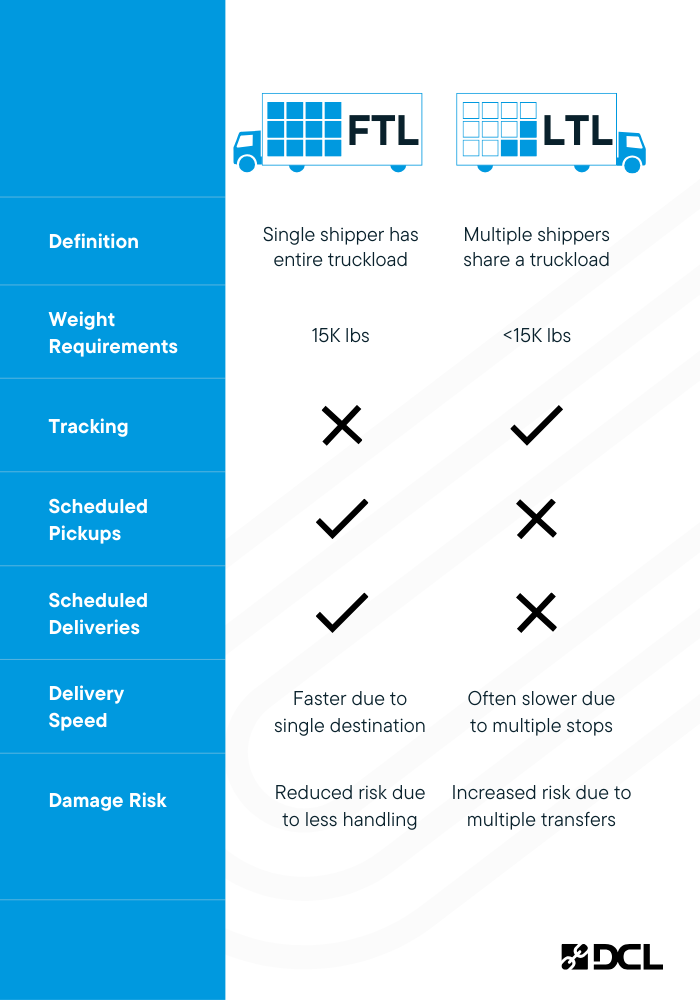

LTL refers to less-than-truckload. LTL is when multiple shippers’ freight is on the same trailer rather than having a single company’s freight exclusively on an individual trailer. Several LTL shipments are combined into one truck to fill it as near to capacity as possible. This is a great option for shipments that are between one and six pallets or any shipment that is less than 14 linear feet because it makes the most out of the available shipping space on a given truck. This is a beneficial for the shipping needs of small businesses.

FTL refers to full truckload freight. FTL shipping is commonly used for large shipments that require taking up the entire truck, or at least close to it. With FTL, your freight is the only freight moving on an individual truck so you have exclusivity to the entire truck and theoretically are filling the truckload. You can reserve the truck with its full capacity even if you don’t require filling up the entire available space. Doing so would ensure that you won’t have to worry about your goods changing hands at any time or your goods being stuck with other products.

Differences Between LTL and FTL

The biggest difference between LTL and FTL is that LTL gives you higher cost savings when you ship only a few pallets at a time. This is cheaper for you because you are only paying for the space you are using, rather than paying for a full truck that isn’t filled to capacity. LTL carriers have to maintain efficiency by filling the excess space with other shipments, so they get as close as possible to maximizing the available space on their trucks.

LTL and FTL have a key difference when providing carrier transit times. If you have a full truckload your carrier will pick up whatever you are shipping and drive it straight to the receiver—this makes transit very predictable. However, the transit for LTL does not go directly to the end customer because of all the different stops they have to make, so the actual delivery date may be very different than the estimated delivery date.

FTL carriers will arrange a firm delivery time since they are only picking up one shipment. Since trucking carriers handling LTL shipments have to pick up and deliver at multiple locations, their pick-up times will occur in a broader window and will require more flexibility on your end.

Another difference is that with a full truckload the shipper will load your product at the point of origin, seal the trailer, and take it straight to its delivery destination. With an LTL shipment, your product will typically be loaded and unloaded in and out of trailers and warehouses not just once but several times before reaching its final destination. This means there is an increased amount of handling and exposure which means a greater chance that your products could incur damages, especially if they are sensitive or fragile.

How to Optimize Your Options: LTL vs. FTL

There are specific times when you should use LTL or FTL. There are no hard and fast rules by which you must abide by, however, there are certain situations where full truckload freight might be more appropriate than LTL.

If you are shipping more than six pallets at a time, then the full truckload option is going to be best for you. If your product is fragile and you need to avoid excessive loading and unloading by multiple carriers, the full truckload option is going to be best for you because you know that your fragile products are the only items within that truck.

If you need firm delivery and pick-up dates the full truckload option is going to be better because you can reserve a single carrier to transport your items. For time-sensitive delivery dates, you absolutely want the full truckload option.

If you have a smaller shipment that is anything less than six pallets you will experience higher cost savings using the LTL method. If you have some flexibility on the delivery or shipping date the LTL option is going to be much better suited for you as well. By giving you a pickup and delivery range at either end, as opposed to requiring a more specific time schedule, you can benefit from the savings of combining your shipment with another shipment.

It is important to be aware of how likely your products could incur damage during shipment. You want to make sure that they are sturdy enough for regular handling at various points throughout the shipping process or that they’ve been properly packaged so that being handled regularly is unlikely to cause any damage.

“By moving our inventory to Louisville, we got a much higher proportion of our freight to a lower cost option. We were able to see significant cost savings because of Louisville’s excellent location.”

How to Work with a 3PL for LTL and FTL Shipments

As you have read, understanding and deciding which of these two freight options is best for your business can be a very complicated undertaking. Because of that, partnering with a third-party logistics provider (3PL) can often be the best option when it comes to shipping LTL or FTL freight, especially when shipments have special requirements or time sensitive deadlines. 3PL companies provide an advantage for businesses looking to find the most competitive rates in the market, along with service that they can count on. Here are a few benefits of using a 3PL to handle your freight shipments.

Expertise

Freight shipping is often a core competency of many 3PL providers, both LTL and FTL included. They have the experience to be able to determine the best way to handle your freight since they provide that service every day. A 3PL helps many different clients handle their freight shipping and have visibility into different products, issues and other factors that determine the best option for your company. This experience helps them evaluate your shipping and choose the most efficient option and anticipate potential risks or higher costs.

Cost Savings

Your company might only ship a few pallets each month to a smaller area, while a 3PL is shipping a significantly higher volume across the whole country or internationally on a daily basis. Their volume and buying power gives 3PL leverage when negotiating rates with freight carriers. By partnering up with a 3PL, you get access to these cost-effective rates.

Visibility

It’s crucial for any business to know what is happening with their freight at any point in time. Many companies are afraid of the loss of control when using a 3PL for LTL or FTL. The reality is you gain more visibility into where your shipment is than you might have had trying to manage the process yourself. A team of professionals will focus on providing the highest level of service to your company, including detailed updates from your shipment’s inception to when it reaches its endpoint.

Bottom Line

The final decision between FTL and LTL shipping will depend on costs, timing and handling requirements for your freight shipment. In many cases, LTL will provide a cheaper option for smaller loads, but if your load is heavy for its size, irregular in shape or takes up more than half of a truckload, it makes sense to get pricing for both options. Sometimes, full truckload is the way to go even if your load leaves empty space on the truck.

If you’re looking for a 3PL with fulfillment centers in cities across the US, we own and operate facilities in The Bay Area, Los Angeles, and Kentucky. Use DCL’s national footprint of warehouses to distribute your inventory across the country to reduce transit times and save on shipping costs. If you need fulfillment or shipping support and want to partner with DCL Logistics, we’d love to hear from you.

Tags: freight